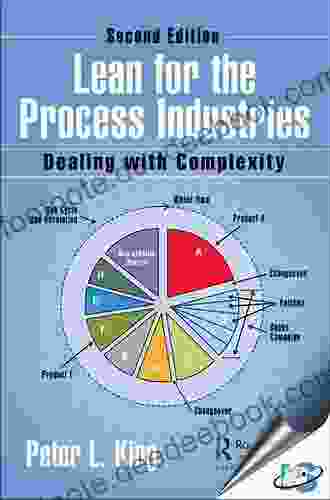

Developing a Lean Culture in the Process Industries: A Comprehensive Guide

4.6 out of 5

| Language | : | English |

| File size | : | 19907 KB |

| Print length | : | 346 pages |

| Screen Reader | : | Supported |

In today's competitive business landscape, process industries face increasing pressure to deliver high-quality products and services while minimizing costs and maximizing efficiency. Implementing a lean culture has emerged as a powerful strategy for organizations seeking to achieve these goals and gain a competitive advantage.

What is Lean Culture?

Lean culture is a philosophy and set of principles that focus on continuous improvement, waste reduction, and value creation. It emphasizes identifying and eliminating non-value-added activities, known as waste, throughout the value stream. By fostering a culture of continuous learning and improvement, organizations can unlock significant benefits, including increased productivity, reduced costs, and improved customer satisfaction.

Benefits of Implementing a Lean Culture in Process Industries

Implementing a lean culture in process industries offers numerous advantages, including:

- Enhanced efficiency: Lean culture promotes the elimination of waste and non-value-added activities, leading to increased efficiency and reduced cycle times.

- Reduced waste: By identifying and eliminating waste in all its forms, organizations can minimize raw material consumption, energy usage, and inventory levels.

- Improved quality: Lean culture emphasizes a focus on quality throughout the production process, resulting in reduced defects and improved product quality.

- Increased flexibility: Lean principles empower employees to respond quickly to changes in demand and market conditions, enhancing flexibility and adaptability.

- Improved safety: By eliminating waste and unnecessary steps, lean culture can reduce safety hazards and improve overall workplace safety.

- Increased profitability: The combination of increased efficiency, reduced waste, and improved quality leads to increased profitability and long-term sustainability.

Key Principles of Lean Culture

The following principles are central to developing a lean culture in process industries:

- Value stream mapping: Identifying and mapping the entire value stream from raw material acquisition to customer delivery helps identify and eliminate non-value-added activities.

- Just-in-time (JIT) production: Production is scheduled and executed to meet actual customer demand, eliminating excess inventory and waste.

- Continuous improvement (Kaizen): A culture of continuous learning and improvement is fostered, with all employees encouraged to identify and eliminate waste and improve processes.

- Total productive maintenance (TPM): Engaging employees in maintaining and optimizing equipment, ensuring maximum uptime and reducing disruptions.

- 5S methodology: A set of workplace organization principles that promote orderliness, cleanliness, and standardization, improving efficiency and safety.

Overcoming Challenges in Implementing Lean Culture

Implementing a lean culture in process industries poses certain challenges that need to be addressed:

- Resistance to change: Employees may resist changes to established processes and practices, especially if they fear job loss or reduced responsibilities.

- Lack of understanding: A clear understanding of lean principles and their benefits is essential for successful implementation. Lack of understanding can lead to resistance and skepticism.

- Cultural barriers: Process industries may have a deep-rooted culture that resists change and innovation. Overcoming cultural barriers requires strong leadership and effective communication.

- Lack of resources: Implementing a lean culture may require additional resources, such as training, technology, and process optimization tools.

Best Practices for Implementing Lean Culture

Successful implementation of a lean culture requires a systematic approach and a strong commitment from leadership:

- Create a strong foundation: Develop a clear vision and establish a dedicated team to lead the lean transformation.

- Develop a roadmap: Outline a comprehensive plan with specific goals and milestones for implementing lean principles.

- Empower employees: Encourage employee involvement and empower them to identify and eliminate waste in their work areas.

- Provide training and education: Ensure employees have a thorough understanding of lean principles and methodologies.

- Establish metrics and measurement systems: Track key performance indicators (KPIs) to monitor progress and identify areas for improvement.

Case Studies of Lean Implementation in Process Industries

Numerous process industries have successfully implemented lean culture, resulting in significant improvements in efficiency and profitability:

- Chemical industry: Dow Chemical implemented lean principles to reduce inventory by 25%, improve productivity by 15%, and save millions of dollars in costs.

- Pharmaceutical industry: Merck & Co. adopted lean manufacturing techniques to reduce drug production time by 50%, improve product quality, and increase profitability.

- Food industry: PepsiCo implemented a lean culture to reduce waste by 30%, increase production capacity, and improve customer satisfaction.

Developing a lean culture in process industries is a strategic imperative for organizations seeking to enhance efficiency, reduce waste, and achieve long-term sustainability. By embracing lean principles and fostering a culture of continuous improvement, process industries can unlock significant benefits, gain a competitive advantage, and deliver superior value to their customers.

4.6 out of 5

| Language | : | English |

| File size | : | 19907 KB |

| Print length | : | 346 pages |

| Screen Reader | : | Supported |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Text

Text Genre

Genre Reader

Reader E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Preface

Preface Manuscript

Manuscript Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Encyclopedia

Encyclopedia Dictionary

Dictionary Character

Character Resolution

Resolution Catalog

Catalog Borrowing

Borrowing Periodicals

Periodicals Study

Study Scholarly

Scholarly Reserve

Reserve Reading Room

Reading Room Study Group

Study Group Dissertation

Dissertation Storytelling

Storytelling Awards

Awards Reading List

Reading List Book Club

Book Club Theory

Theory Jon Cohen

Jon Cohen Juliana Brandt

Juliana Brandt Heather Gardam

Heather Gardam Edward Keynes

Edward Keynes Joseph Cassis

Joseph Cassis Kyriakos Anastasiadis

Kyriakos Anastasiadis J T Skye

J T Skye Amy Chang

Amy Chang Krassimir T Atanassov

Krassimir T Atanassov Megan Stephens

Megan Stephens Lynda Lahman

Lynda Lahman Wallace Edwards

Wallace Edwards Raymond C Floyd

Raymond C Floyd Dr Sandeep Jatwa

Dr Sandeep Jatwa Lea Rawls

Lea Rawls Ann Ehrlich

Ann Ehrlich Peter Brennan

Peter Brennan Haley Lukas

Haley Lukas Kathleen M Fallon

Kathleen M Fallon Joni Darc Shepherd

Joni Darc Shepherd

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Allen GinsbergUnveiling the True Meaning of Enough: A Comprehensive Guide to Fulfillment...

Allen GinsbergUnveiling the True Meaning of Enough: A Comprehensive Guide to Fulfillment... Simon MitchellFollow ·18k

Simon MitchellFollow ·18k Anton ChekhovFollow ·16.2k

Anton ChekhovFollow ·16.2k Ben HayesFollow ·17k

Ben HayesFollow ·17k Colin FosterFollow ·10.8k

Colin FosterFollow ·10.8k Bob CooperFollow ·7.3k

Bob CooperFollow ·7.3k Charles DickensFollow ·4.7k

Charles DickensFollow ·4.7k Allan JamesFollow ·17.5k

Allan JamesFollow ·17.5k Stan WardFollow ·16k

Stan WardFollow ·16k

Allen Ginsberg

Allen GinsbergUnveiling the True Meaning of Enough: A Comprehensive...

: In the relentless pursuit of progress and...

Clay Powell

Clay PowellHawker Hunter: The Jet Fighter that Shaped British...

Nestled in the halls of aviation...

Alec Hayes

Alec HayesWhen and How to Use Lean Tools and Climb the Four Steps...

Lean is a management...

Trevor Bell

Trevor BellVolume of Charlotte Mason Original Homeschooling: A...

Charlotte Mason's original...

John Parker

John ParkerAscending Tristan da Cunha: A Comprehensive Guide to...

Prepare yourself for an extraordinary journey...

4.6 out of 5

| Language | : | English |

| File size | : | 19907 KB |

| Print length | : | 346 pages |

| Screen Reader | : | Supported |